Global solutions in handling & automation for the Aluminium industry

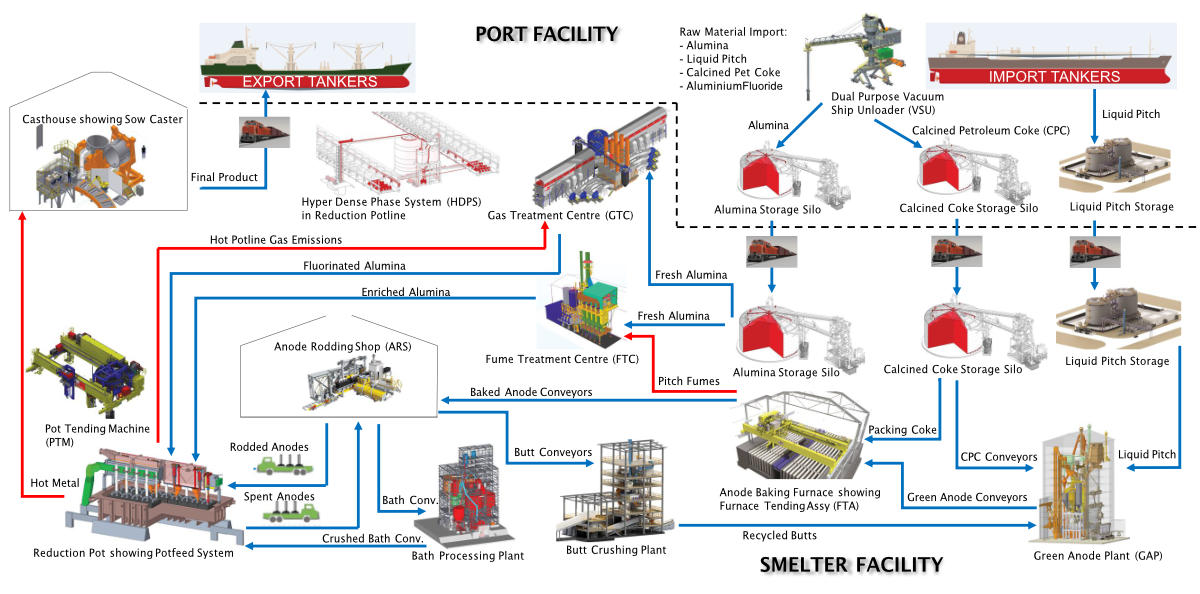

Through REEL Alesa, NKM Noell, REEL Möller, Anode & Casting, and ICS, we cover the full aluminium process—offering customised handling solutions that drive automation, enhance smelter performance, and protect worker safety.

Sustainable Aluminium Technologies

We harness automation, real-time monitoring, and sustainable technologies to optimise aluminium production. Our solutions enhance operational efficiency, ensure precision across processes, and support long-term environmental responsibility—helping our clients meet evolving industry standards while improving performance and reducing their carbon footprint.

Enhancing precision, efficiency, and safety in aluminium handling through intelligent, automated systems.

Through intelligent sensors and analytics, our smart monitoring systems improve accuracy, enable proactive maintenance, and boosts productivity.

Reducing environmental impact across aluminium operations through the integration of energy-efficient and low-emission technologies.

Our Technology Centres

Discover our cutting-edge Global Technology Centres, supplying, developing, installing and maintaining REEL Aluminium products and services for the greater aluminium industry.

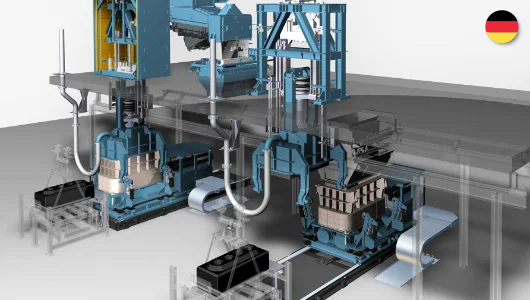

REEL provides advanced solutions for green anode production, offering full-scale technologies for both new-builds and facility upgrades. Whether custom-engineered to your flowsheet or delivered as a turnkey system, our plants are built on decades of innovation and experience. With industry-leading vibrating compactor technology, REEL systems ensure consistent, high-quality anodes with excellent operational reliability and efficiency.

We also design high-performance carbon recycling plants for butts and green scrap recovery, tailored to meet the demands of modern aluminium smelters. Our robust, low-maintenance systems support everything from conceptual studies to complete EPC delivery, helping clients achieve operational excellence and meet their environmental commitments.

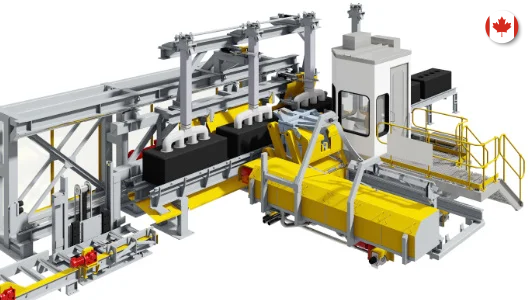

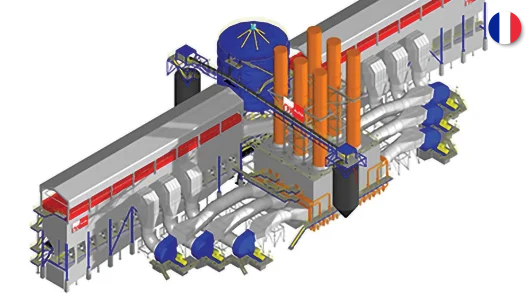

REEL delivers fully integrated solutions across the aluminium smelter value chain, from anode rodding and handling to bath processing and casting. Our anode rodding shop systems are built to maximise productivity and safety, while our anode handling equipment ensures seamless, automated transport of green and baked anodes. Each solution is tailored to your layout, rigorously tested, and backed by over 40 years of industry expertise to reduce downtime, lower maintenance costs, and deliver lasting value.

Our bath processing plants use advanced crushing, dosing, and dust-control technologies to maintain consistent bath quality and boost pot performance. In the cast house, REEL’s proven ingot and sow casting systems, including the world’s largest automated sow caster—are scalable, modular, and designed for operational efficiency. With a strong focus on environmental control, safety, and performance, REEL’s proprietary equipment supports the most demanding aluminium production environments.

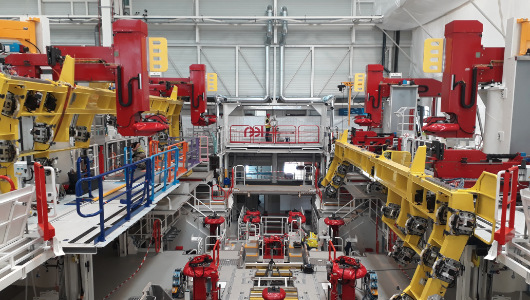

REEL delivers precision-engineered solutions to support every stage of potroom operations in aluminium smelters. Our Pot Tending Machines are trusted worldwide for performing complex potline tasks, such as anode changing, crucible handling, and cover removal, with maximum safety, automation, and efficiency. Complementing this are our robust Transfer Gantry Systems, enabling safe and seamless movement of equipment between potrooms and maintenance zones under extreme environmental conditions.

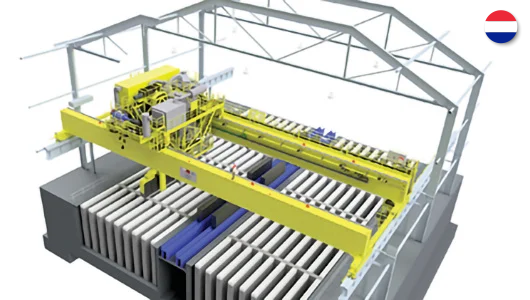

REEL delivers a comprehensive range of advanced equipment for anode handling and bake furnace operations in aluminium smelters. Our Furnace Tending Assembly (FTA) enables efficient, low-emission coke loading and anode handling with full-cycle functionality, from loading and extraction to flue wall maintenance. Engineered for extreme environments, the FTA features gravity-operated grabs, dust control below 4 kg/tonne, and precision control systems. Complementing this, our Anode Stacking Crane (ASC) supports intermediate storage and transfer of up to 22 anodes per cycle, offering high flexibility and automation across paste plants, furnaces, and rodding shops.

To further support flue wall maintenance, REEL offers specialised tools designed for both safety and performance. The Flue Wall Maintenance Platform (FWMP) spans multiple pits and provides secure access for technicians using integrated man lifts and cross-travel bridges. For post-bake cleaning, the Flue Wall Brushing/Cleaning Machine (FWBM/FWCM) removes coke build-up efficiently using motorised wire brushes, powered and positioned via the FTA. Together, these systems form a reliable, fully integrated solution for high-performance smelter operations.

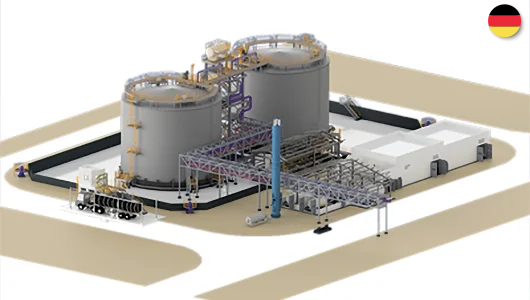

REEL delivers advanced ship loading and unloading solutions, integrated with high-performance Material Handling Systems (MHS) to support the aluminium industry’s most demanding port and terminal operations. Our pneumatic ship unloaders and loaders handle materials such as alumina, petroleum coke, and fluorides with capacities up to 2,500 tph – ensuring dust-free transfer, environmental compliance, and operational efficiency. Combined with full-scale port logistics systems and vehicle loading/unloading stations, REEL provides complete, turnkey solutions from ship to silo to truck, all designed to optimise bulk material flow with minimal loss or disruption.

At the core of our bulk handling offering are REEL’s storage silos and anti-segregation feed systems, engineered to preserve material integrity and ensure consistent discharge. These systems are seamlessly integrated with dense-phase pneumatic conveying, automated feed controls, and modular truck stations to deliver safe, low-maintenance performance across the entire value chain. Backed by decades of global experience, REEL’s MHS and unloading technologies support smelters in achieving cleaner operations, stable process control, and improved productivity from port to potroom.

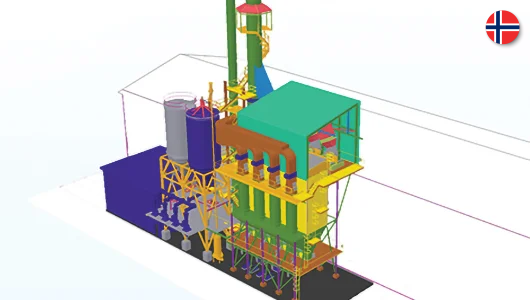

REEL’s Environmental Control Systems are designed to meet the aluminium industry’s most demanding emission standards while supporting long-term operational efficiency and sustainability. At the heart of these solutions are our advanced Gas Treatment Centres (GTCs) and Fume Treatment Centres (FTCs), which use proprietary technologies to capture and recycle fluoride, sulphur, and particulate emissions from potlines and anode baking processes. Modular and customisable, these systems are adaptable to various plant layouts and can be integrated with alumina adsorption and filtration technologies to ensure regulatory compliance and resource recovery.

Complementing these systems are REEL’s high-performance GTC Heat Exchangers, including AHEX and NHEX models, which replace traditional water-cooling towers with dry-cooling technology. These exchangers not only stabilise gas flow and reduce corrosion risk, but also contribute to energy recovery and environmental conservation. Whether implemented in new smelter builds or as upgrades to ageing systems, REEL’s environmental control solutions are proven, scalable, and built to support cleaner, more efficient aluminium production.

REEL provides a comprehensive portfolio of material handling equipment and solutions designed to support every stage of aluminium production – From raw material intake at ports to precision delivery in the potroom. Our systems include Direct Pot Feed (DPF) technology for efficient alumina dosing, advanced silo designs with anti-segregation features, and dense-phase Pressure Vessel Systems for energy-efficient long-distance transport. Whether handling alumina, petroleum coke, or bath materials, each solution is engineered for reliability, minimal maintenance, and seamless integration into existing plant operations.

To support logistics across road, rail, and water, REEL offers high-capacity Truck and Railcar Loading/Unloading Stations, Ship and Barge Loading/Unloading Systems, and vertical Pneumatic Elevators – all designed with dust suppression, automation, and environmental compliance in mind. Complementing this is the Möller Fluidflow® system for low-pressure, continuous conveying and the intelligent MÖLLER® Turbuflow® control system, which reduces energy use and wear. Together, these technologies form a complete, high-performance handling network tailored to the needs of modern aluminium smelters and terminals.

REEL’s Hyper Dense-Phase System (HDPS™) and solid-phase conveying technologies are engineered to deliver high-capacity, low-maintenance material transport for aluminium smelters. With low air consumption and fully enclosed pipelines, these systems preserve material integrity, reduce dust and wear, and support continuous, energy-efficient flow from silos to pot hoppers across complex plant layouts. Designed for both horizontal and vertical configurations, they offer scalable solutions that enhance process reliability and integrate seamlessly into new or existing facilities.

In parallel, REEL supports decarbonisation through Carbon Capture, Utilisation & Storage (CCUS) technologies targeting emissions from potline operations—particularly those from anode combustion. Despite the low CO₂ concentration in smelter off-gases (~1%), solvent-based capture methods such as chilled ammonia are showing promise in pilot programmes. Especially effective at smelters near carbon hubs or storage sites, CCUS can reduce potline emissions by up to 90% and plays a key role in the aluminium industry’s journey toward low-carbon production.

Key Facts

With a global footprint of more than five manufacturing sites, a workforce of 2,400+ skilled professionals, and a strong commitment to safety through 120+ annual training sessions, REEL Aluminium Division stands as a trusted leader in industrial excellence worldwide.

An extensive network of over 5 manufacturing sites worldwide.

Boasting a large talent pool of more than 2400 highly skilled employees.

REEL accommodates over 120 safety training session annually.

Innovation in Aluminium Handling Solutions

For decades, REEL Aluminium has led innovation in the aluminium industry, delivering high-performance, end-to-end solutions that drive efficiency, reliability, and safety. Our expert teams combine deep industry knowledge with advanced engineering and cutting-edge technology to meet evolving production needs.

Through strategic acquisitions and global brands, REEL Alesa, NKM Noell, REEL Möller, and Anode & Casting, we’ve expanded our expertise across the full primary aluminium process, from raw material handling to casting. With 2,400 specialists and five manufacturing sites worldwide, we deliver customised systems that optimise performance, reduce costs, and ensure safe, sustainable operations for greenfield and brownfield smelters.

Global Support Offices

Our advanced Global Support Offices ensure the successful installation, commissioning, and long-term maintenance of all REEL and REEL Aluminium projects worldwide. Strategically located near major industrial centres, these offices provide rapid response, expert technical assistance, and tailored service solutions to meet the specific needs of each site. With dedicated teams of engineers and field specialists, we offer ongoing operational support, system optimisation, and remote diagnostics – maximising equipment uptime and performance across the full lifecycle of our solutions.

Al Shafar Tower 1, Unit 1301- 1302 Barsha Heights (TECOM), P.O.Box 336108, Dubai, United Arab Emirates

+971 4 447 9955

Al Fanar, Office 34, building Y98, Block 939, Riffa Hajyat

+973 63330010

Building 20, Zone 24, Floor 2 Office، 840، 5 Al Rawabi St, Doha, Qatar

+974 3312 2806

Room 702-03-B, 7F, Building A, No 518, Kunming Rd., Shanghai

+86 592 8061629

50 Gheringhap Street, Geelong, 3220, Victoria

+61 4 1932 5474

Unit No 14, Floor 12A, Tower 1, PS Srijan Corporate Park Tower 1, Block GP-2, Sector-V, Salt Lake, Kolkata- 700091, West Bengal, India

+919831063508