Advanced lifting solutions to meet the high standards of the Nuclear Industry

Our equipment is designed and manufactured with the highest levels of safety and operational performance, ensuring reliability and excellence at every stage of operation.

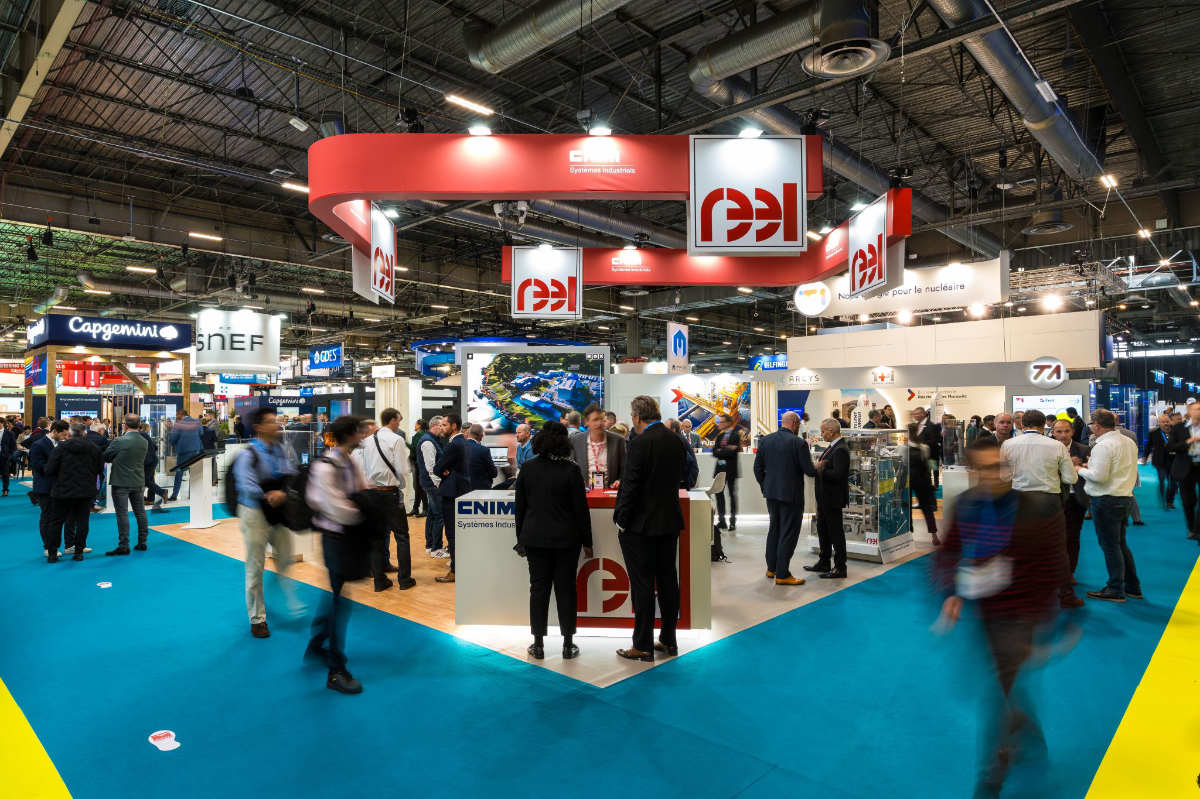

WNE 2025 – REEL at the heart of global nuclear industry

At the 2025 World Nuclear Exhibition, REEL announced strategic partnerships and shared expertise with international stakeholders. Explore the highlights and our commitment to sustainable nuclear energy.

A Comprehensive Presence

REEL is involved across the entire nuclear fuel cycle. Our teams bring deep expertise and in-depth product knowledge, working hand-in-hand with our clients.

REEL designs lifting and handling equipment tailored to nuclear reactors, ensuring operational safety and reliability.

As a recognized specialist, REEL develops customized solutions for the handling and production of nuclear fuel, combining innovation, precision, and strict adherence to standards.

With expertise in the nuclear fuel cycle, REEL develops custom equipment for managing the end-of-cycle processes, waste storage, and decommissioning operations in highly constrained environments.

Expertise, Innovation, and Training at the service of the Nuclear Industry

REEL is a leader in the design and manufacture of complex handling and lifting systems.

We design each piece of equipment according to our customers’ precise specifications and requirements, integrating all key stages: functional analysis, operational safety analyses, preliminary design, calculations, detailed design, and manufacturing.

Our design offices and operators work in close synergy to assemble, test, simulate, and dry-run the equipment, including under degraded conditions.

We also capitalize on feedback from our maintenance activities to integrate maintainability requirements into the design from the outset.

This approach enables us to guarantee high-performance, reliable equipment that complies with the highest safety and security standards in the nuclear sector.

Our training center, the REEL Academy, enables us to train our own teams and those of our customers, pass on knowledge and expertise, and provide training that is fully tailored to the needs of our sector.

Over 50 Years of Expertise in the Nuclear Fuel Cycle

REEL designs high-security lifting and handling equipment for the most constrained environments, including:

- Shielded cells

- Irradiated zones

- Robust designs resistant to strong radiation exposure

With nuclear-grade manufacturing facilities, we produce durable equipment designed for maintainability and operational safety, ensuring compliance in highly regulated zones.

Safely handling radioactive materials

REEL develops high-security handling equipment specifically designed for handling radioactive materials in sensitive, confined, or irradiated environments. Each solution meets strict nuclear safety requirements while ensuring operator protection and operational traceability.

Our Expertise Includes:

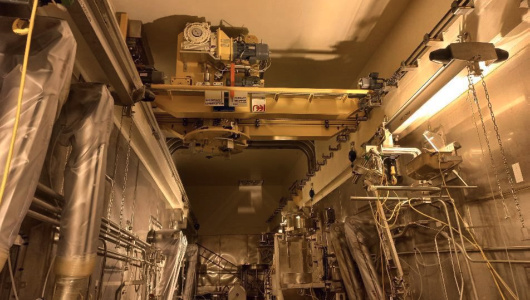

- High-Security Cranes and Gantries: For the handling of fuel casks.

- Hot Cell Overhead Cranes: Including Zone 4 cranes.

- Special Equipment: Such as polar cranes, transfer carts, and traversers.

- Submerged Waste Recovery and Conditioning Systems.

- Glove Boxes and Specialized Tools: For cutting, welding, and handling in nuclear environments.

Tailored equipment for the nuclear industry’s unique needs

REEL designs and delivers a comprehensive range of lifting, handling, and processing equipment tailored to the specific demands of the nuclear sector, combining security, reliability, and technological innovation.

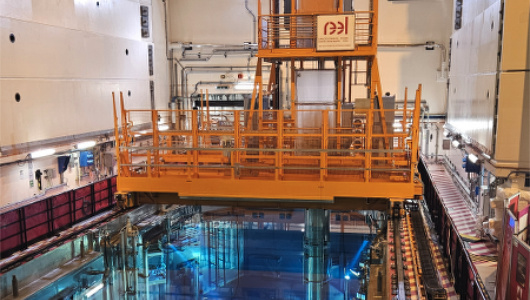

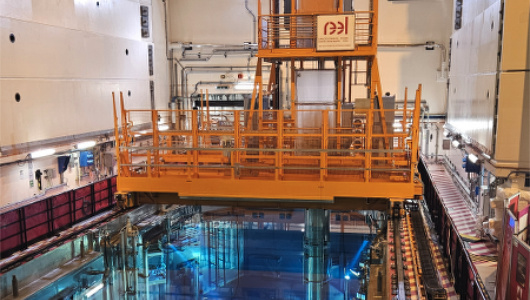

Custom technological solutions designed for the secure handling of both new and used fuel assemblies in nuclear power plants.

REEL designs, installs, and maintains specialized bridges for the lifting and transport of major components, such as reactor vessel covers, steam generators, and fuel rods. These systems ensure high precision and uncompromising reliability.

REEL designs and manufactures high-precision equipment for operations inside shielded cells used in nuclear environments. These systems enable the secure handling of sensitive or radioactive materials in confined, high-toxic environments while ensuring operator safety and adherence to strict industry standards.

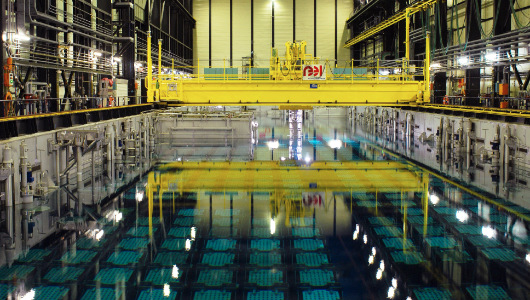

REEL develops specialized equipment for underwater handling and intervention in nuclear environments. Designed for the manipulation and transport of components or materials submerged in water (e.g., fuel storage pools or reactors), these systems combine durability, precision, and safety, ensuring reliable operations while meeting stringent technical and regulatory requirements.

REEL designs and produces glove boxes—airtight enclosures equipped with integrated gloves—that allow operators to safely handle sensitive, contaminated, or radioactive materials in confined settings. These solutions ensure a physical barrier between the operator and hazardous substances while maintaining high levels of operational precision. Tailored for the nuclear industry’s requirements, REEL’s glove boxes offer customized, reliable, and safety-compliant solutions.

REEL’s nuclear traversers are critical tools for safely transferring spent nuclear fuel, radioactive waste, or other sensitive materials within nuclear facilities. These systems ensure secure transfer between specific areas, including:

- Storage pools

- Shielded cells

- Storage containers

- Buildings within a site

Designed for highly regulated environments, these traversers integrate advanced control technologies to ensure millimeter-level precision and operational safety. Each traverser is customized to meet the specific needs of our clients.

REEL designs bespoke complex systems for submerged waste recovery and conditioning. These solutions ensure secure, efficient, and precise handling of waste materials while adhering to stringent safety and radioprotection standards.

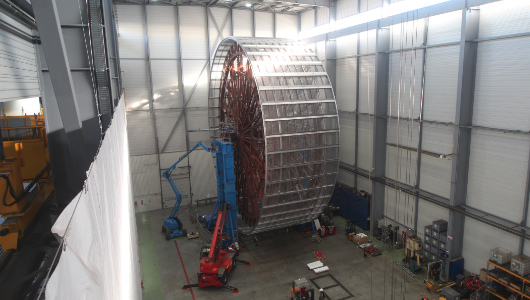

REEL produces tailor-made equipment for cold source systems, such as trash racks and drum screens, ensuring optimal water filtration. These solutions protect installations from debris, enhancing reliability, performance, and durability for both industrial and nuclear infrastructures.

Integrated Solutions for the Nuclear Industry

From design to manufacturing, installation, commissioning, and maintenance, our teams support every stage of the nuclear fuel cycle.

For over five decades, REEL has pioneered innovative, safe, and sustainable solutions to meet the nuclear sector’s highest standards.

Conducted in France and internationally (China, South Africa, Belgium, Finland, Sweden), across all reactor types.

Highly skilled experts committed to providing personalized support at every project stage, worldwide.

Aiming for Zero Incidents

As a trusted provider to the major players in the nuclear sector, REEL prioritizes the health and safety of its employees and partners, fostering a culture of shared responsibility. A dedicated safety team supervises all activities across our facilities and client sites.

Design and Manufacturing of Mechanical Systems and Equipment

CNIM Systèmes Industriels, a major player in the nuclear sector in France and globally for over 40 years, designs, manufactures, installs, and commissions mechanical systems and equipment for leading nuclear organizations.

Areas of Expertise:

- Secure handling systems

- Complex metal fabrication

- ESPN-compliant equipment

- Operation tooling fabrication

- Integration of advanced systems

CNIM Systèmes Industriels — Brégaillon Port Zone — CS 60208 — 83507 La Seyne-sur-Mer Cedex – FRANCE