REEL NKM Noell: Aluminium Industry

REEL NKM Noell Special Cranes delivers advanced lifting and handling systems for the aluminium industry, specialising in potroom cranes, bath and metal handling, and anode-related equipment. With decades of engineering expertise, the company provides safe, precise, and reliable technologies that improve smelter productivity and operational continuity. From design and manufacturing to installation and lifecycle support, REEL NKM Noell Special Cranes ensures high-performance, durable solutions tailored to the demanding conditions of primary aluminium production.

Potroom Cranes

REEL NKM Noell Special Cranes delivers high-performance potroom cranes engineered for all critical smelter operations, including anode changing, metal tapping, bath handling, and pot maintenance. Each crane integrates precise lifting mechanisms, advanced automation, and robust control systems to ensure safe, efficient, and repeatable operation in harsh potline environments. Offered as new installations or modernisation projects, these cranes are recognised worldwide for their reliability, long service life, and ability to enhance productivity and operational stability across aluminium smelters.

Furnace Tending Solutions

We provide robust furnace tending solutions designed for efficient, safe, and continuous operation in aluminium casting and melting areas. Each system is engineered to manage critical tasks such as charging, skimming, stirring, and cleaning, while ensuring precise control and minimal heat loss. Integrated with reliable lifting mechanisms and advanced automation, these solutions support consistent furnace performance and reduced operator exposure. Offered as standalone equipment or complete modernisation packages, they are recognised for their durability, ease of maintenance, and ability to improve workflow and overall plant productivity.

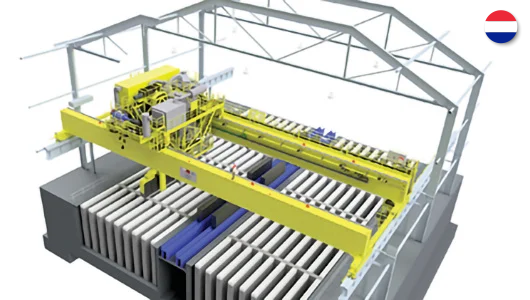

Anode Handling Equipment

We deliver specialised anode handling equipment engineered for the safe, precise, and efficient movement of new and spent anodes across the smelter. Each system manages lifting, transport, positioning, and exchange tasks with accuracy, reducing manual intervention and maintaining steady process flow. Built for harsh potroom conditions and supported by advanced control options, these solutions offer reliable performance and long service life. Provided as standalone units or as part of integrated anode management systems, they enhance safety, productivity, and overall operational efficiency.

Metal & Bath Processing and Handling Solutions

Our metal and bath processing and handling systems are engineered for safe, reliable, and continuous material flow within aluminium smelters. Designed to manage the transfer of molten metal, bath material, and related by-products, each system ensures stable operation with minimal process interruption. With durable construction and precise control technologies, these solutions perform consistently in demanding environments. Available as individual components or integrated handling lines, they enhance workflow efficiency, operational safety, and overall potline performance.

Automated Process Technologies

We offer automated process technologies that combine advanced control, automation, and digital systems to boost productivity and consistency across smelter operations. Designed to support potroom, furnace, and material-handling activities, these solutions provide precise process control, real-time monitoring, and improved decision-making. With intelligent sensors, robust software, and seamless equipment integration, they reduce manual intervention and enhance operational safety. Available as standalone upgrades or part of broader digitalisation packages, they deliver higher efficiency, greater reliability, and long-term process optimisation.

Modernisation & Upgrades

Our modernisation and upgrade solutions extend equipment lifecycles, enhance performance, and maximise the value of existing smelter assets. Focused on crane retrofits, control system upgrades, and mechanical improvements, these services boost reliability, safety, and operational efficiency. Each upgrade package is engineered to meet current production demands while integrating advanced technologies and improved components. Delivered with minimal disruption to operations, our modernisation solutions offer a cost-effective path to higher performance, longer service life, and sustained operational stability.

Installation & Commissioning

REEL NKM Noell Special Cranes provides installation and commissioning services that ensure complete turnkey delivery, from detailed design and manufacturing through to final on-site start-up. Each project is executed by experienced teams who manage precise assembly, rigorous testing, and smooth integration into existing operations. With a strong focus on safety, quality, and schedule adherence, we minimise downtime while securing reliable performance from day one. These end-to-end services support long-term efficiency and operational stability across every installation.

Maintenance & After-Sales Support

We support our customers long after installation by providing dependable maintenance and responsive after-sales services. From routine inspections and condition assessments to rapid spare parts delivery and operational troubleshooting, we help keep equipment running safely and efficiently. Our teams understand the demands of aluminium smelters and work closely with clients to prevent unplanned downtime and maintain high performance. Whether through scheduled service programmes or targeted interventions, we ensure your lifting and handling systems remain reliable throughout their lifecycle.

Contact us

REEL NKM Noell Special Cranes™

Rudolf-Diesel- Str.1

97209 VEITSHOECHHEIM

GERMANY

Tel. : +49 931 40473 0

Fax : +49 931 40473 1000

Hein-Saß-Stieg

9

21129 HAMBURG

GERMANY

Tel : +49 40 2393 6819 11

REEL NKM Noell Special Cranes™

Kruisweg 643

2132 NC HOOFDDORP

THE NETHERLANDS

Tel. : +31 206 550 030

Our News

Follow REEL’s key projects, innovations and highlights in France and around the world.

REEL Academy: Lifelong Learning for Industrial Excellence

World Nuclear Exhibition 2025