Industry & Environment : sustainable solutions

REEL covers the entire lifecycle of industrial and environmental installations. Our solutions range from the design of automated lifting systems to the modernisation of existing units, including maintenance and customer support.

Our areas of expertise

For decades, REEL has been supporting industry and environmental players with robust, automated, or robotic solutions adapted to the most demanding environments. Our teams design, manufacture, and maintain customised equipment for a variety of sectors, from steel to paper and transportation.

Turnkey industrial equipment: Custom machines, welding solutions, cranes, automated systems and grabs designed to optimise the handling of waste, biomass, bulk materials and sludge.

Upgrades and technological retrofits extending the lifetime of equipment while enhancing energy efficiency and operational performance.

Preventive and corrective maintenance programs, 24/7 technical assistance, remote monitoring of equipment, spare parts supply and operator training.

Adapting to every industrial and environmental process

REEL designs and manufactures automated or robotic special-purpose machines, as well as a wide range of custom-made equipment for a variety of industrial applications.

• Double-girder and single-girder overhead cranes,

• Gantries,

• Jib cranes,

• Monorails,

• Hoists,

• Winches,

• Automated handling systems and special cranes for waste,

• Biomass and bulk materials.

Recognised expertise in France and globally

With teams based in Europe and North America, REEL deploys lifting and handling solutions across all continents. Backed by more than 75 years of experience, we are a trusted partner for industries and operators in waste-to-energy, biomass, and sustainable production facilities.

of experience in lifting and handling solutions.

with integrated supervision: optimising productivity, reducing operating and maintenance costs

including production sites with 371,354 sq ft of manufacturing and assembly workshops, as well as service centers in Europe, North America, Asia, and the Middle East.

Reference solutions

Building on extensive experience in North American and international markets, REEL now delivers large-scale, complex engineering projects worldwide.

Through the combined expertise of REEL MC Levage, REEL CMF, REEL COH and REEL NKM Noell, we design and implement solutions adapted to the specific constraints of each industrial and environmental site, ensuring performance, safety and sustainability.

A team of experienced engineers and technicians operates on-site across France and other regions globally, ensuring the maintenance and expertise required for all your industrial equipment.

Complete range of single-girder and double-girder overhead cranes, with lifting capacities up to 150 tons.

Custom-built gantries for heavy or specific loads, with full automation available when required.

Robust and reliable equipment for applications ranging from simple lifting tasks to operations in extreme or controlled environments.

Automated cranes using state-of-the-art technologies and AI (artificial intelligence) to detect contaminants in waste recycling, with grabs or buckets, designed for incineration plants, biomass facilities and anaerobic digestion units : slag cranes, refuse cranes, bulky waste cranes, container cranes.

Wide range of multi-shell, hydraulic or bucket grabs for handling waste, sludge, biomass and bulk materials.

Automatic rolling machines for steel, stainless steel, aluminum, zinc, titanium, or Inconel sheets, with thicknesses ranging from 0.5 to 10mm and lengths up to 3m, capable of producing 600 pieces per hour.

Automated rolling and longitudinal welding lines for the production of cylinders from sheet metal. A complete range of rolling and welding lines, offering piece-by-piece or continuous production (from medium to very high-volume series, producing 10 to 300 pieces/hour). Processes include TIG, MIG, and laser welding.

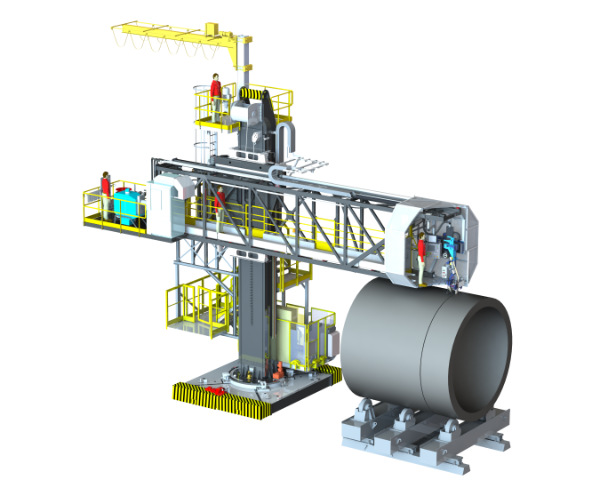

Turnkey specific comprehensive welding solutions, integrating:

- Welding or cladding heads, Narrow GAP heads,

- Flux feeding and recycling units,

- Workpiece positioning tools: positioners, rotators…

- Preheating equipment,

- Support structures for welding heads (trolleys, booms, gantries…),

- Operator access and workstations (platforms, cabins, control stations),

- Control and process management units for welding (seam tracking, inspection cameras, speed regulation, supervision).

REEL Group references in Industry & Environment

Our News

Follow REEL’s key projects, innovations and highlights in France and around the world.

REEL Academy: Lifelong Learning for Industrial Excellence

World Nuclear Exhibition 2025