REEL ALESA: Leading Edge Materials Handling Technologies

Lifting, Conveying & Storage Solutions

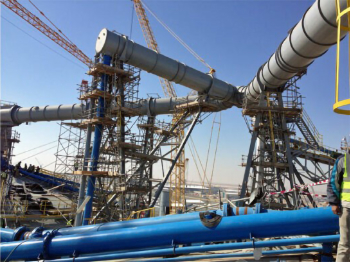

REEL Alesa is a global leader in integrated materials handling and process plant solutions, delivering conveying systems, dosing devices, and loading and unloading equipment. Serving the power, mining, steel, cement, fertiliser, and aluminum industries, the company combines robust engineering with advanced technologies to enhance efficiency and sustainability. From design and installation to commissioning and support, REEL Alesa enables clients worldwide to boost performance while reducing environmental impact.

Tailor-made Solutions with High Performance

At the core of REEL ALESA’s expertise are tailor-made solutions built for high performance. Each system is engineered to meet specific client needs, from complex conveying routes to demanding bulk materials.

The company provides advanced conveyors, precision dosing devices, and high-capacity loading and unloading systems that ensure efficiency, reliability, and dust-free operation. Its capabilities also cover large storage facilities, energy-efficient centrifugal blowers, and turnkey process plants for smelters.

By combining custom engineering with proven technologies, REEL ALESA delivers productivity, safety, and environmental responsibility across every project.

Why Choose REEL ALESA

At REEL Alesa, we don’t just supply components, we ensure your entire operation is supported throughout its lifecycle.

Largest pneumatic ship unloaders (up to

1,500 t/hr) for the aluminium industry.

Design to delivery of complete system and

plant solutions.

Best in class innovative solutions that respect a Zero Harm culture.

Our Primary Products & Services

REEL ALESA delivers customised materials handling systems and end-to-end services that ensure reliable performance, efficiency, and long-term support for industrial operations worldwide.

REEL Alesa delivers advanced bulk storage solutions in both concrete or steel silos and domes, with capacities up to 100,000 tonnes. Each facility integrates feed, reclaim, blending, and extraction systems – fluidised or mechanical – ensuring efficient, automated, and low-maintenance operation. Offered as standalone systems or turnkey projects, these storage solutions are recognised worldwide for reliability, rapid installation, and strong economic performance.

We provide dust-free, high-capacity loading and unloading solutions, including the world’s largest pneumatic ship unloaders (up to 1,500 t/h) for the aluminium industry, plus flexible ship loaders and combined units for bulk materials. For land use, they deliver efficient, safe stations for rail cars, trucks, and potroom vehicles, designed for reliability and low dust emissions. Trusted worldwide, their technology reflects REEL

Alesa’s commitment to cost efficiency, innovation, and performance.

REEL Alesa designs and produces economical, low-maintenance conveying systems designed for both simple and complex routes. Their technologies include dilute-phase, dense-phase, hyper-dense (HDPS™), pneumatic elevators, air gravity, and mechanical or hybrid systems. Capable of handling materials from alumina and fluoride to fly ash, cement, and copper concentrate, these solutions are trusted worldwide for efficiency and versatility.

Our designs are reliable, high-precision dosing systems for both fluidisable and non-fluidisable bulk materials, providing flow rates from 0 to 100 tonnes per hour. Their portfolio includes solutions like HDPS™ dosing units, diaphragm dosing systems, pneumatic dosing elevators, and rotary feeders – each engineered to support accurate, controlled feeding across various process applications.

We develop and build custom centrifugal blowers renowned for their reliability, high efficiency, and low-maintenance design. Each unit is engineered to the customer’s exact specifications and paired with unique flow-control devices to deliver exceptional performance, control, and energy savings compared to conventional blowers.

REEL Alesa provides turnkey process plant solutions that optimise smelter operations with energy-efficient, low-maintenance systems. Our bath plants use utogenous crushers, magnetic separators, and enclosed dust-free systems to ensure consistent quality, while carbon recycling plants feature tramp-iron separation, adjustable sizing, automation, and safe enclosed handling for both reprocessing and disposal.

Our Office

Visit or contact us for any inquiries.

For over 50 years, REEL Alesa has designed, installed and maintained complex materials handling solutions and other customised equipment mainly for the aluminium industry but also for sectors of energy, mining, cement, steel and fertilisers.

Our News

Follow REEL’s key projects, innovations and highlights in France and around the world.

World Nuclear Exhibition 2025

REEL supports Airbus in new A320 assembly line