A complete line integrator offer

For over 50 years, REEL has been designing complex lifting and handling systems. Its core positioning: being a line integrator for production and assembly, especially in the aerospace sector.

REEL co-engineers every project with its clients. This collaborative approach ensures performance, reliability, and innovation at every stage of the production cycle.

Digital simulation for better ergonomics

REEL uses a fully interactive digital mock-up, directly connected to its design tools. Every phase of the project is simulated, including operator ergonomics.

Virtual reality is embedded from the earliest design steps. This gives operators a clear view of how REEL’s equipment will match their needs.

Stelia Aerospace: a moving line success story

REEL contributed to the moving assembly line at Stelia Aerospace’s factory of the future in Méaulte. The result: a high-capacity production tool, designed to ensure flow and cadence.

A global maintenance network

REEL has built an international network of maintenance agencies close to major industrial sites:

- Airbus in Saint-Nazaire, Hamburg, and Broughton

- Mobile (Alabama) for the A320

- Montréal and Seattle to support the North American market

Local teams provide fast, expert maintenance. REEL uses advanced tools such as IoT, predictive maintenance, and remote supervision.

REEL, an innovation-driven line integrator

Lean management shapes every project. REEL’s engineering teams start from a blank page to co-create tailor-made solutions with each client.

The group also develops advanced drilling systems for assembly lines. Through the acquisition of Spanish start-up AEI, REEL integrated a vibration-assisted drill. It adjusts drilling parameters in real time, even across complex multi-material stacks.

The result: up to 10× faster processing for key assembly phases.

Line integration at the core of REEL’s strategy

REEL combines expertise in lifting systems and integrated production solutions. It acts as a full-scope industrial partner, offering:

- Design

- Line integration

- On-site maintenance

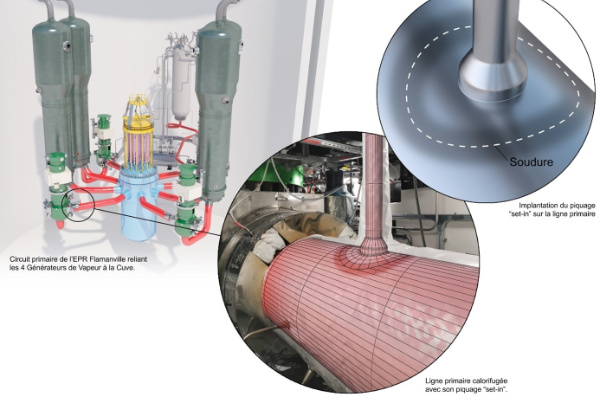

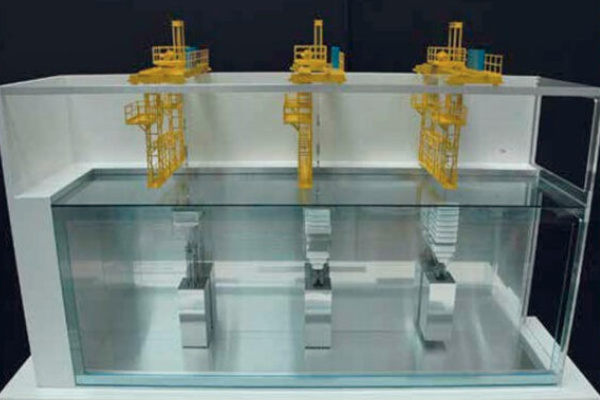

Whether in aerospace, nuclear, or aluminium, REEL supports its clients’ performance—locally and globally.

(Article adapted from a feature published in L’Usine Nouvelle, June 2019.)