REEL MÖLLER

Pneumatic conveying and storage solutions for the mining and adjacent industries

With over 80 years of engineering heritage, REEL MÖLLER® is a global leader in pneumatic conveying technology for fine-grained mineral bulk materials. From alumina and crushed bath to fly ash and biomass, our systems are trusted across industries for their reliability, efficiency, and low-maintenance performance.

Comprehensive Bulk Material Handling Solutions

At REEL MÖLLER®, we deliver high-performance solutions for the transport and storage of fine-grained and abrasive bulk materials across industries such as cement, lime, plaster, power, and metals. Supporting the entire material handling chain—from delivery and storage to conveying and dispatch—we offer advanced systems for truck, wagon, and ship loading/unloading, along with key components like MÖLLER valves, rotary flow control valves, diverter valves, rotary vane feeders, pneumatic elevators, and air gravity conveyors.

Why Choose REEL MÖLLER®

End-to-end service excellence: from project planning to spare parts, REEL MÖLLER® delivers complete lifecycle support for your pneumatic conveying systems.

Thousands of global installations built for

longevity and low maintenance.

Tailor-made conveying systems to meet

complex plant requirements.

Up to 30% energy savings with patented dense-phase technologies.

Our Primary Products & Services

REEL MÖLLER® provides both standardised systems and fully engineered, application-specific solutions designed to meet precise operational parameters and process requirements.

REEL MÖLLER® air gravity conveyors harness gravity and minimal conveying air to efficiently transport fluidised bulk materials at capacities exceeding 2,000 m³/h – delivering reliable, low-maintenance operation with exceptionally low energy demand.

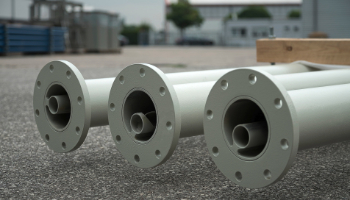

MÖLLER-TURBUFLOW® is a patented dense phase conveying system designed for high efficiency and reliability. Its inner bypass pipe enables continuous fluidisation, preventing blockages and allowing safe restarts even with a fully loaded pipeline, ideal for low-wear, high-capacity transport.

MÖLLER FLUIDFLOW® enables low-velocity, high-capacity dense-phase conveying at pressures above 3.5 bar. Ideal for abrasive materials and Direct Pot Feeding, it ensures smooth, energy-efficient transport with minimal wear, attrition, and segregation – safely combining gravity flow with pressurised operation.

Engineered for vertical transport of fine bulk materials, the MÖLLER® Pneumatic Elevator achieves heights over 100m and throughputs up to 800t/h. Its pressure-driven design ensures reliable, dust-free conveying for cement, lime, ash, and aluminium industries.

MÖLLER® loading systems provide dust-free, high-capacity loading of powdery bulk materials onto trucks, trains, or ships. With adjustable lift heights, flexible

configurations, and integrated dust extraction, they ensure safe, efficient, and clean dispatch operations up to 2,000 t/h.

Our Office

Visit or contact us for any inquiries.

Founded on Johannes Möller’s groundbreaking dry bulk feed pump, MÖLLER® has grown into a global leader in pneumatic conveying. With thousands of systems worldwide, specialising in advanced solutions for cement, fly ash, alumina, and mineral handling.

Our News

Stay updated with our latest news and innovations!

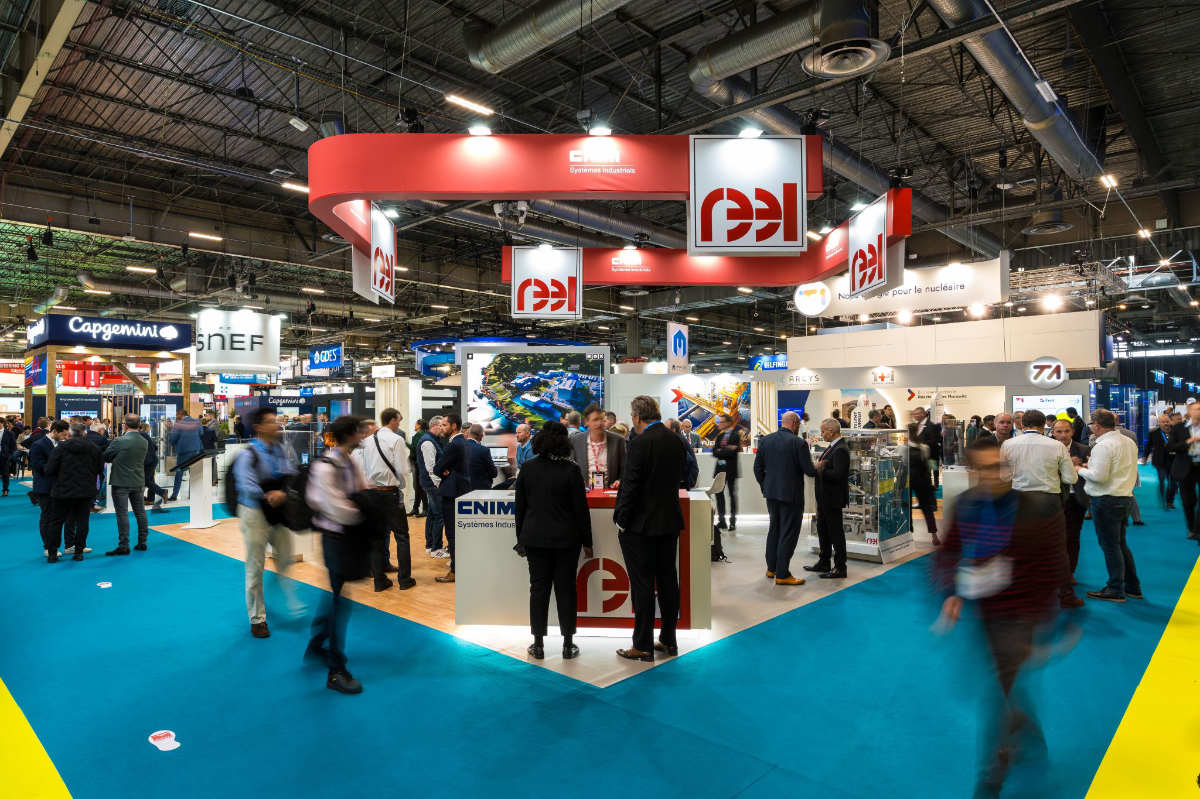

World Nuclear Exhibition 2025

REEL supports Airbus in new A320 assembly line