With 40 years of experience in front and back end cycles in the nuclear industry, as far as the dismantling process.

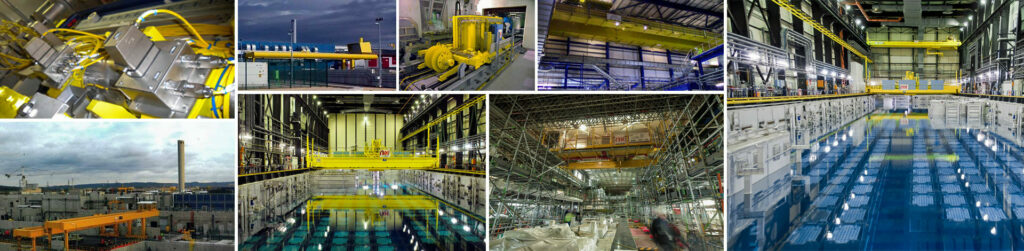

REEL supplies handling equipment and complete systems for the front and back end cycles in nuclear power plants, as well as for laboratories and research reactors. Within these fields, the environmental restrictions on irradiated media render direct interventions on or around the equipment impossible.

REEL has built up a solid foundation of experience, under all conditions, to guarantee the functioning and repair of equipment within the irradiated zone. Our solutions take into account the strict design requirements (safety, containment, radiological protection, the release of heat, space and reduced access) as well as operational restrictions (operational safety, accurate positioning, automated remote control, ability to undertake repairs, integrated logistical support).

Front end fuel cycle

REEL provides process and handling equipment for uranium enrichment and fuel manufacturing installations.

References

Back end fuel cycle

REEL produces process and handling equipment for re-processing sites as well as lifting units for hot cells in installations used for the packaging, treatment and storage of nuclear waste.

This equipment is based upon proven technologies in order to provide the highest possible levels of availability in difficult operating conditions with extremely restricted access. These technologies require the reliability and redundancy of components, their compatibility with irradiated environments and electro-magnetic compatibility.

An important part of the design involves monitoring and system automation. The equipment is controlled jointly by hard-wired logic and programmable electronics (PLCs, controllers, digital systems). REEL closely monitors future developments of all software used.

References

REEL Norway team has been very proud to receive The Minerals, Metals & Materials Society award at TMS Annual Meeting

Ship Unloader Upgrade Success: Alba & REEL ALESA Achieve Milestone in Operational Excellence!

We are present at ARABAL 2023 in Riyadh and available to address any of your needs. potlines, anode production, ports