REEL supplies cranes for different reactor buildings

REEL is involved in the modernization of these cranes, updating them to the latest earthquake resistance standards, strengthened safety standards, or improved operational performance standards.

The techniques proposed for the lifting systems (hoists, instrumentation & control) meet the highest safety and reliability standards, supported by an optimized human-machine interface.

References: modernization of polar cranes via our entity NKMNOELL Special Crane:

REEL carries out all the safety studies needed to meet sub-criticality requirements and the integrity of stored fuel: criticality, earthquake resistance, drop resistance, thermo-hydraulic & radiological factors.

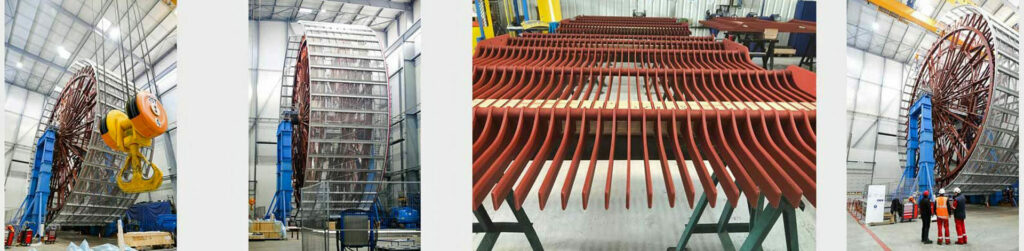

Our technology is based upon the separation of neutron-absorbing functions and resistance functions, using borated steel as a neutron poison and a specific design to resist earthquakes. The racks designed by REEL are also used for re-racking operations.

REEL designs and manufactures spent fuel storage racks for cooling pools.

References :

More than 18,000 cells, equipping nearly 30 reactors across the world.

REEL manufactures components for reactor internals

In a plant dedicated to the production of complex mechanical systems in stainless steel, notably the guide tubes for new reactors and replacement operations.

References

More than 1,600 guide tubes supplied for French (EDF) and Chinese plants.

REEL with its subisdiary NFM Systems, design and manufacture Reactor Building containment equipment such as :

> Personnal airlocks

> Equipment hatches

REEL proposes filtration solutions for new reactors and replacement operations :

REEL Norway team has been very proud to receive The Minerals, Metals & Materials Society award at TMS Annual Meeting

Ship Unloader Upgrade Success: Alba & REEL ALESA Achieve Milestone in Operational Excellence!

We are present at ARABAL 2023 in Riyadh and available to address any of your needs. potlines, anode production, ports