60 years of experience as a global leader in Aeronautics

REEL plays a key role in all major stages of the aeronautics value chain, providing comprehensive project management and delivering high-quality solutions to aircraft manufacturers and airlines. By anticipating technological shifts, REEL leads in aeronautic innovation and services.

Working together; Flying further

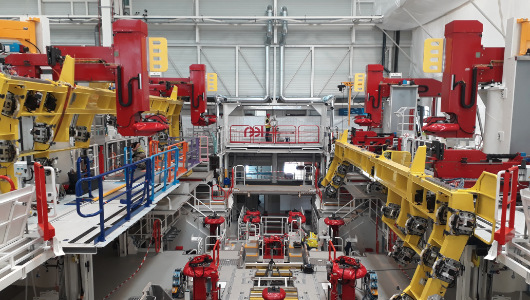

REEL designs full assembly lines for aircraft manufacturers, delivers complete maintenance installations for airlines and MRO, in addition to offering a wide range of industrial services. It also provides advanced portable and robotic drilling systems.

This unique combination of capabilities lets REEL support aircraft production and operational phases, providing integrated high-performance solutions at each aeronautics lifecycle stage.

Bringing together a full range of capabilities – including design production, supply chain coordination and commissioning – complemented by integrated services.

Services and operational maintenance of assembly lines, fully equipped hangars, paint shops, and other facilities for manufacturers and airlines.

Delivering proven, cutting edge solutions that enhance precision, flexibility and efficiency in production processes, ensuring sustainable performance over time.

Tailored innovative Aeronautics solutions

We provide advanced aerostructure integration solutions, from PreFAL to FAL, ensuring precision and efficiency at every step.

Our in-house, measurement-based assembly method guarantees consistent quality and full compliance from the first assembly. To support critical operations, we design and manufacture high-precision, custom tooling that meets the most demanding technical requirements.

Additionally, our smart mobility solutions enhance production agility by offering innovative and adaptable mobile systems, fostering streamlined logistics and greater operational flexibility for our customers’ production lines.

Custom Aeronautics Solutions: Supporting Manufacturers, Airlines, and MROs

From design to delivery, we deliver end-to-end project management, offering cutting-edge, high-performance solutions trusted by aircraft manufacturers and airlines worldwide.

We provide end-to-end integrated assembly solutions, from Pre-FAL to FAL, designed to optimize manufacturing processes and meet the highest industry standards.

We design and manufacture specific and custom tools, adapted to the most stringent technical requirements, in order to support our customers in the control of their critical operations.

We offer a comprehensive range of maintenance solutions, including docking systems, telescopic platforms, and GSE/GTE supply, designed to ensure safety and optimize operations.

Backed by a specialized aeronautical team, our flexible, multi-aircraft installations adapt to your unique needs. With a global network, we deliver tailored services for all your equipment worldwide.

A team of expert service engineers works on-site across France, Germany, the UK, and the USA, ensuring the maintenance of all industrial equipment while striving daily to optimize your production.

The REEL “Class Alpha” is new generation hoist (NGH) system engineered for commercial and military helicopters, integrating state-of-the-art technology to enhance safety, performance and maintainability.

REEL AEI designs and manufactures Electronic Drilling Units (EDU) for portable and light robotic applications. These two-axis machines can drill holes up to 24 mm in a single pass and feature advanced functions like adjustable cutting parameters, vibration reduction, automatic layer detection, and countersink depth correction.

A strong presence in Aeronautics, with decades of trust from proven partnerships

We ensure end-to-end project management, delivering high-quality and high-performance solutions to aircraft manufacturers and airlines alike.

in Europe (Toulouse, IDF, , North America (Mirabel, Mobile) & Asia

over 30 customers locations

Essentials pillars to lead all our projects to success

Safety is our top priority: the protection of people lies at the core of our development process, ensuring a secure and ergonomic work environment at every stage, in compliance with ISO 45001 standards.

Customer satisfaction drives us to tailor every solution to not only meet but exceed our clients’ expectations. With a focus on quality, our certified processes – EN 9100 & ISO 9001– guarantee seamless execution throughout the entire project lifecycle.

We prioritize performance by continuously optimizing methods for maximum efficiency and sustainability.

Through employee training, supported by our internal REEL Academy, we cultivate cutting-edge expertise and innovation.

Outstanding achievements

- Final Assembly Line for the A350 XWB, A330 and A330 NEO at Airbus Toulouse,

- System Equipping Line A350XWB, A220 & A321 XLR for Airbus,

- Moving line A320 for Airbus,

- Test & finishing stations for FAL A380 pour Airbus Toulouse,

- Paint docks for the A320 family at Airbus Hamburg,

- Falcon 10 X Wing for DASSAULT,

- Teleplateform for QATA Airways,

- New program for BOEING.

Other customer references