A successful turnkey project in a complex context

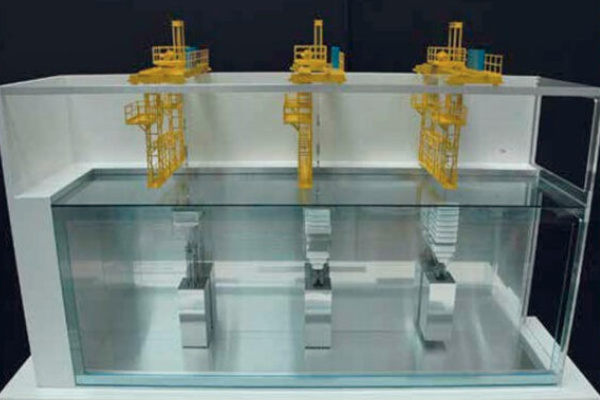

After ten months of on-site work, REEL and its partner ORYS have completed the installation of new nuclear storage racks at EDF’s Penly power plant.

This turnkey operation covered the full project scope: design studies, manufacturing, equipment supply and on-site assembly.

Despite health constraints linked to the COVID-19 lockdowns, the teams delivered the project on time, with full technical compliance and zero accidents.

Safety-driven design and engineering for these new racks

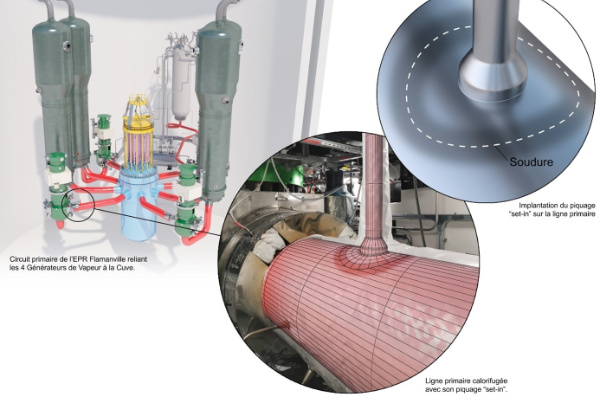

REEL conducted all the required safety studies to ensure compliance with nuclear standards. These included:

- Criticality assessments to maintain sub-criticality

- Seismic and drop resistance

- Thermohydraulic performance

- Radiological impact

The racks are designed to separate the neutron absorption function from mechanical strength.

Boron steel, used as a neutron-absorbing material, ensures both seismic resistance and regulatory compliance.

Flexible, high-performance nuclear storage racks

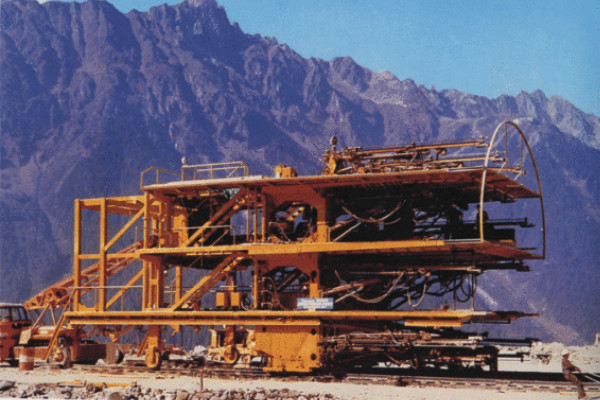

REEL’s technology is designed to support reracking operations as well.

These storage racks can be adapted to different configurations and are built to meet the evolving needs of nuclear facilities.

A collective success, powered by strong collaboration

This project was made possible by close coordination between REEL, ORYS, EDF Penly and DIPDE Marseille.

From engineering to manufacturing, every team played a key role in delivering a project that strengthens the site’s long-term energy continuity.

REEL thanks EDF for its continued trust.