1,500 tonnes. That’s the equivalent of four fully loaded Boeing 747s — and also the weight that the new ITER overhead crane, installed in the assembly hall of the fusion reactor, is capable of lifting. A world-class technical achievement supporting one of the most ambitious scientific projects of the 21st century.

Precision Installation of the ITER Overhead Crane

To lift the four 47-meter girders and their motorized trolleys into place 43 meters above the ground, a high-capacity crawler crane (1,000 tonnes) was deployed. Positioned outside the building, its boom reached over the roof through a custom opening. The 10-day installation combined brute mechanical force, cutting-edge technology, and artisanal precision — the final positioning of each girder was completed by hand, using ropes for millimetric accuracy.

A Crucial Role in Assembly and Future Dismantling

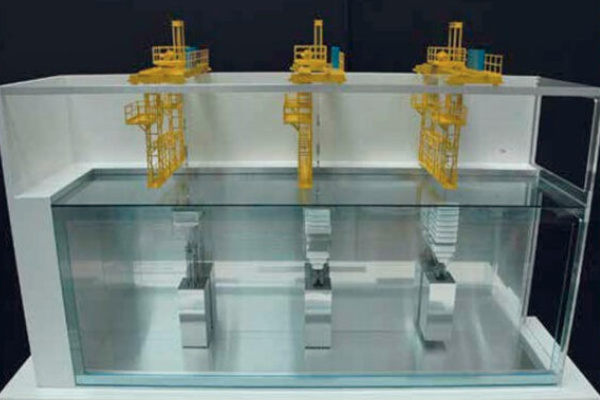

Built by a consortium led by French company REEL, the ITER overhead crane will be pivotal in two major phases: the assembly of the tokamak, starting in 2019, and the future dismantling of the reactor, expected around mid-century. Its unmatched lifting capacity enables the handling of the heaviest components of the machine — from 1,250-ton cryostat sections to 1,200-ton pre-assembled segments including vacuum vessel sectors and vertical TF coils.

Rails Extended to Serve the Tokamak Pit

Once the adjacent Tokamak Building reaches its full height (only the two basement levels are completed as of now), the crane rails will be extended by another 80 meters. This will allow direct positioning of massive components above the assembly pit, ensuring maximum safety, control, and precision.