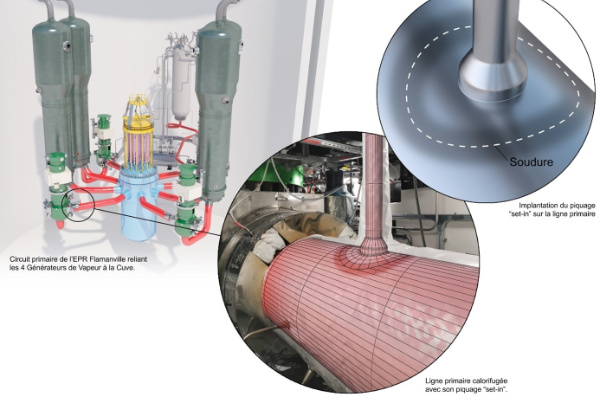

In February 2023, a key milestone was reached at Flamanville 3: EDF completed the installation of three heavy-duty support clamps on the reactor’s main primary circuit. Designed to prevent a major breach in the event of an accident, these components were manufactured by REEL in a record time at its La Rochelle facility.

Meeting EDF and ASN’s nuclear safety requirements

In early 2021, Framatome was tasked with designing a specific support clamp to meet the nuclear safety requirements imposed by ASN (France’s Nuclear Safety Authority). These clamps had to reinforce three sensitive points on the main primary circuit of the EPR reactor.

After ASN approved the technical solution, Framatome placed the order with REEL in October 2021. The manufacturing of these complex parts became a critical path item for the commissioning of Flamanville 3.

Only 11 months to deliver the EPR support clamp, with zero compromise on quality

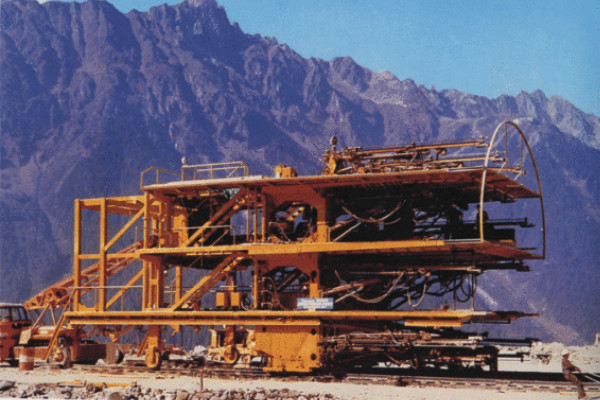

Despite a highly constrained schedule, REEL delivered all three support clamps within 11 months, fully aligned with the original timeline. The parts were produced under the most stringent quality and safety standards, reflecting REEL’s longstanding industrial expertise in the nuclear sector.

Close-up of a REEL clamp on the Flamanville EPR

Proud to contribute once again to Flamanville 3

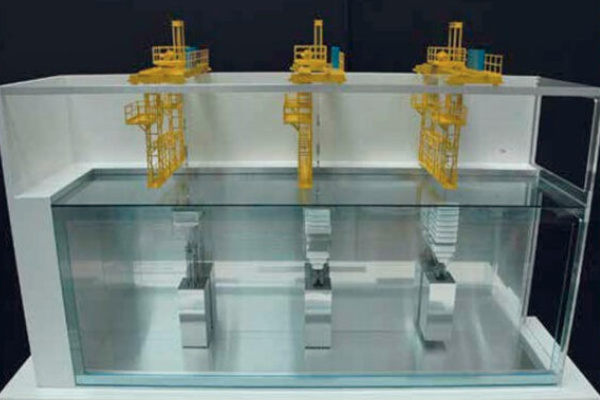

This project continues REEL’s long-standing partnership with EDF. REEL had already supplied all the critical equipment used for fuel assembly loading and unloading, both in the fuel building and the reactor building.

Our teams are proud to have successfully delivered this demanding project, in close collaboration with Framatome and EDF.

Learn more

> Flamanville EPR – Design deviation of three main primary circuit connections