Electrolysis Cranes

REEL delivers precision-engineered solutions to support every stage of potroom operations in aluminium smelters. Our Pot Tending Machines are trusted worldwide for performing complex potline tasks, such as anode changing, crucible handling, and cover removal—with maximum safety, automation, and efficiency. Complementing this are our robust Transfer Gantry Systems, enabling safe and seamless movement of equipment between potrooms and maintenance zones under extreme environmental conditions.

To further support pot maintenance and lifecycle needs, REEL offers Raising Girder Systems for secure superstructure lifting and Pot Shell Lifting Beams designed for safe, accurate pot handling. All systems are engineered for high-load performance, easy integration, and operator safety, ensuring smooth operations with minimal downtime across your facility.

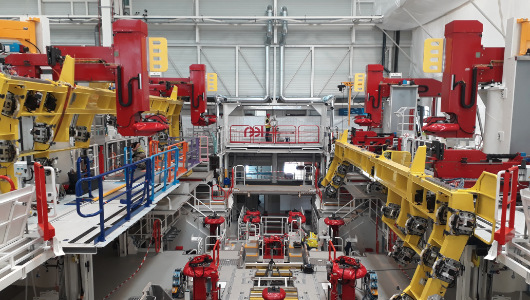

Pot Tending Machines

REEL’s Pot Tending Machines are designed to perform all critical potline operations with high precision, safety, and reliability. Custom-engineered for all pot technologies and

amperage levels, our PTMs support automated or manual operation and deliver unmatched flexibility in anode changing, pot cover handling, crucible and frame lifting, and deck plate cleaning. With robust modular construction, advanced tool control systems, and over 30 years of proven service life, REEL PTMs are trusted by leading aluminium smelters worldwide for optimal potroom performance.

Transfer Gantry Systems (TGS)

REEL’s Aluminium Transfer Gantry Systems ensure the safe, efficient transfer of pot tending machines between potrooms and maintenance areas. Engineered for extreme environments, our systems support loads up to 500 tonnes and feature retractable bumpers, wireless communication, and PLC control. Available as end or middle gantry configurations with rail lifting beam systems, they offer reliable performance, easy maintenance access, and seamless integration with your plant layout.

Veitshoechheim Technology Centre

Visit or contact us for any inquiries

Raising Girder Systems

REEL’s Raising Girder Systems are designed to lift and support pot superstructures during pot shell replacement or maintenance, ensuring maximum safety and structural stability. With robust hydraulic or electromechanical actuation and precise control systems, these solutions provide secure, reliable lifting under extreme operational conditions.

Customised to fit your potroom configuration, REEL raising girders offer easy integration, minimal downtime, and compliance with the highest industry standards.

Pot Shell Lifting Beams

REEL’s Pot Shell Lifting Beam is a specialised solution designed to handle the safe and precise lifting of pot shells during maintenance, replacement, or transfer operations

within aluminium smelters. Built to withstand the harsh conditions of potroom environments, the lifting beam offers exceptional strength, stability, and compatibility with various crane systems and pot designs. Engineered for ease of operation, it allows for accurate alignment and positioning, helping maintenance teams perform critical tasks efficiently while minimising downtime. It can be customised to suit specific plant layouts and operational requirements, ensuring seamless integration into existing lifting workflows.